Precision is paramount in manufacturing, and few technologies deliver the consistency and accuracy that computer numerical control (CNC) machining offers. With its ability to produce complex parts with tight tolerances, CNC machining is an indispensable tool for industries ranging from aerospace to medical devices.

But what does CNC machining do, exactly? Understanding how CNC machining works helps manufacturers leverage this powerful technology to scale production.

CNC machining is a subtractive manufacturing process where a computer-controlled machine instrument cuts off material from a workpiece to produce a desired part based on digital designs. Unlike additive manufacturing methods such as 3D printing, which build up layer by layer, CNC machining begins with a solid block of material and removes excess portions to achieve the final shape.

A typical CNC machining setup consists of three main elements:

CNC machining can handle a broad spectrum of materials, including:

CNC machining can also process materials like wood, composites and even some ceramics, although these may require specialized tools and techniques.

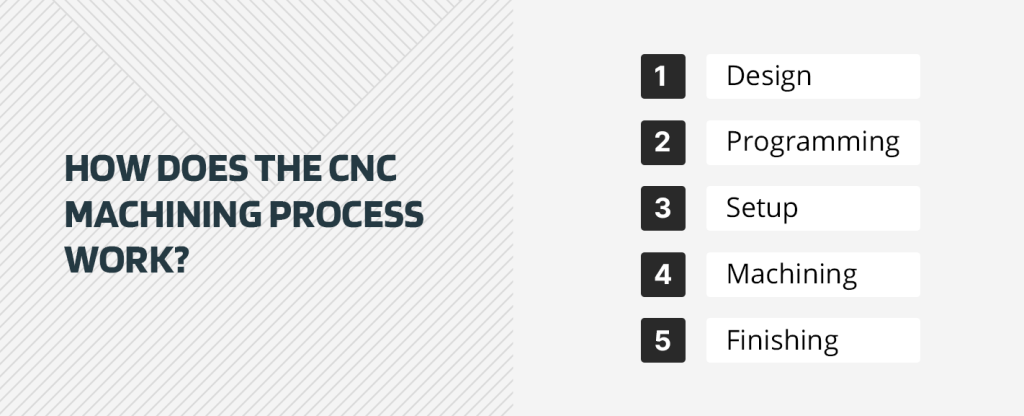

The CNC machining process can be broken down into five key phases.

The first step in CNC machining is creating a CAD model of the desired part. The digital blueprint contains all the necessary geometric information and tolerances. Designing for manufacturability (DFM) is crucial at this stage to ensure the part can be produced using CNC machining.

Once the CAD model is finalized, it is converted into a CNC program using CAM software. The programming process involves selecting the appropriate toolpaths, cutting parameters and machine settings. The resulting program, written in G-code and M-code, provides step-by-step instructions for the CNC machine to follow.

Before machining can begin, the CNC machine must be prepared. The preparation includes fixturing the workpiece securely to the machine table and loading the necessary cutting tools into the machine’s tool magazine. The operator also sets the zero reference point or origin to establish a coordinate system for the part.

With the setup complete, the CNC program is executed. The machine automatically removes material according to the programmed toolpaths. The operator monitors the process, making adjustments to ensure optimal performance and part quality.

After machining, the part may require secondary operations such as:

Quality control measures, including dimensional inspection and surface roughness checks, are performed to verify that the part meets the specified requirements.

CNC machining is used in various industries, enabling the production of high-precision parts and custom components that meet stringent requirements.

In the aerospace industry, CNC machining creates complex, lightweight parts that can withstand harsh light conditions. CNC machines create parts with tight tolerances and excellent surface finishes, from structural components like wing ribs and spars to complex engine parts and landing gear components. The aerospace sector often works with materials like aluminum, titanium and advanced composites, which require specialized machining techniques and tools to achieve the desired results.

The medical sector relies on CNC machining to produce surgical instruments, implants and medical equipment components. Precision is critical in this field, as even the slightest deviation can have fatal consequences for patient safety and treatment outcomes. Additionally, medical devices must be made from biocompatible materials that can withstand sterilization processes and resist corrosion.

CNC machining manufactures engine parts like cylinder heads, transmission gears and suspension components. The ability to produce parts with consistent quality and accuracy is essential in the automotive industry, as it impacts vehicle performance, reliability and safety. CNC machines also create tooling for other manufacturing processes, such as stamping dies and injection molds.

In the electronics industry, CNC machining makes housings, heat sinks and other components for smartphones, computers and industrial control systems. It also produces telecommunications equipment like antenna housings, waveguides and connectors. The ability to machine intricate features and achieve tight tolerances is crucial in this field, as electronic components require precise mating surfaces and heat dissipation properties.

The oil and gas industry relies on CNC machining to produce components for drilling equipment, pipeline systems and refining machinery. These parts must withstand extreme temperatures, high pressures and corrosive environments. CNC machines create complex shapes and maintain tight tolerances in materials such as stainless steel, high-strength alloys and wear-resistant materials like tungsten carbide.

Manufacturers without in-house CNC capabilities can still enjoy the benefits of CNC machining by outsourcing their manufacturing. Outsourcing offers numerous advantages, including:

CNC machining is a powerful technology that enables the production of precise, complex parts for various industries. For manufacturers without in-house capabilities, outsourcing CNC machining to a trusted partner ensures high-quality parts without needing expertise or financial investment.

PBZ Manufacturing provides a full spectrum of manufacturing services, from CNC machining to finishing. Our resourceful manufacturing approach streamlines your supply chain, reducing lead times and manufacturing costs. With decades of experience and a commitment to quality, we have the expertise and resources to handle your most demanding machining projects.

Request a quote today and enjoy one-stop manufacturing for the precision parts you need to drive your business forward.