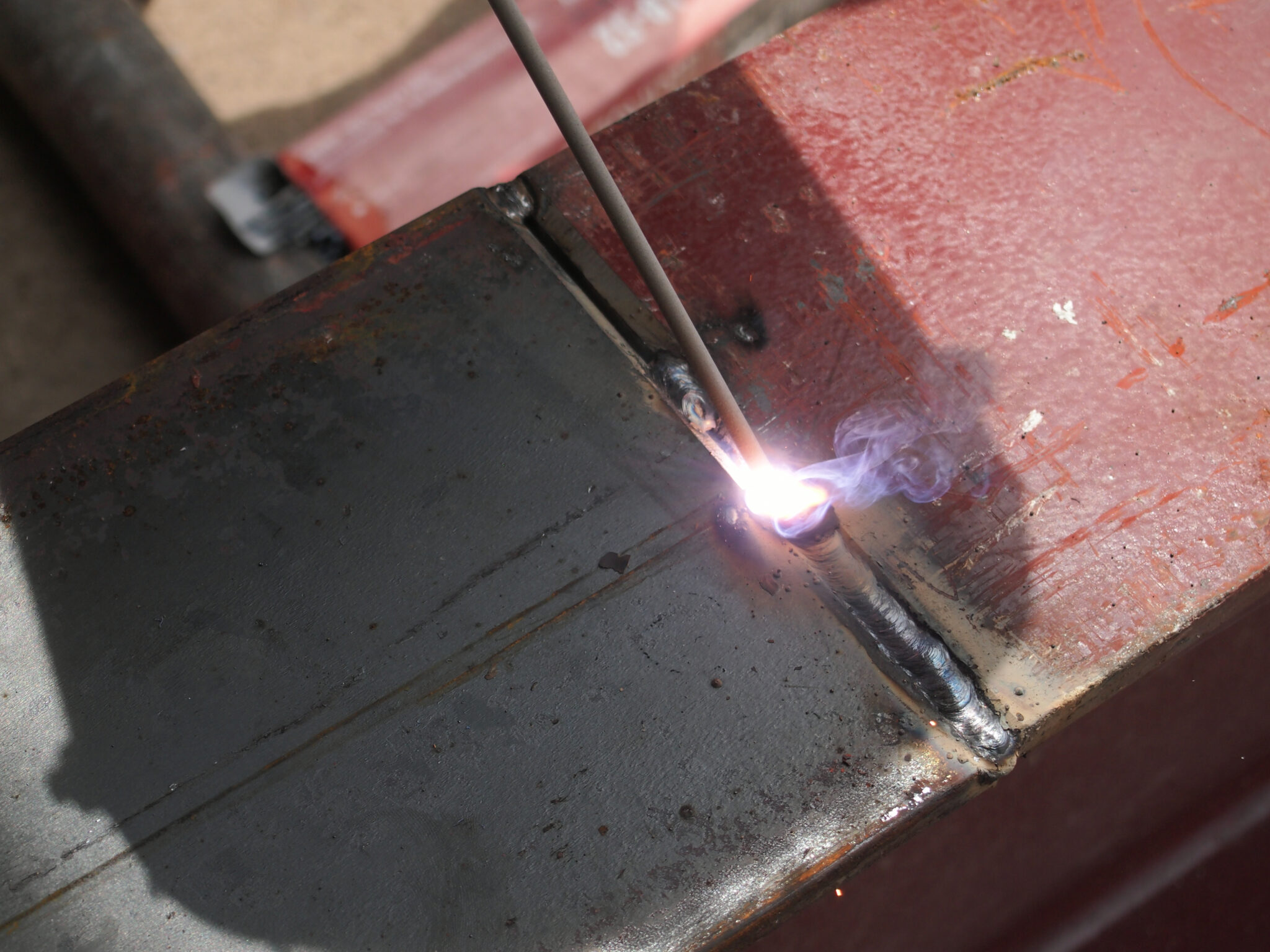

Metal inert gas (MIG) welding involves feeding a wire electrode through a welding gun while simultaneously releasing a shielding gas. This combination creates an electric arc between the wire and the workpiece, melting the wire and fusing the metal to form a strong joint.

MIG welding is known for increased efficiency, speed, versatility and simplicity compared to more complex methods. MIG welding is prevalent in manufacturing settings and is suitable for welding various metal types, including mild steel, aluminum and stainless steel. It is popular in the automotive, construction and manufacturing industries for welding thicker materials like steel.

MIG welding is also well-suited for high-production applications where speed is crucial, such as assembly line manufacturing, as it allows for fast and continuous welding. Because of its ability to create highly durable welds, many companies choose MIG welding for structural fabrication projects, such as building frames and heavy machinery. Additionally, MIG welding is valuable in repair and maintenance work, allowing operators to complete projects faster.

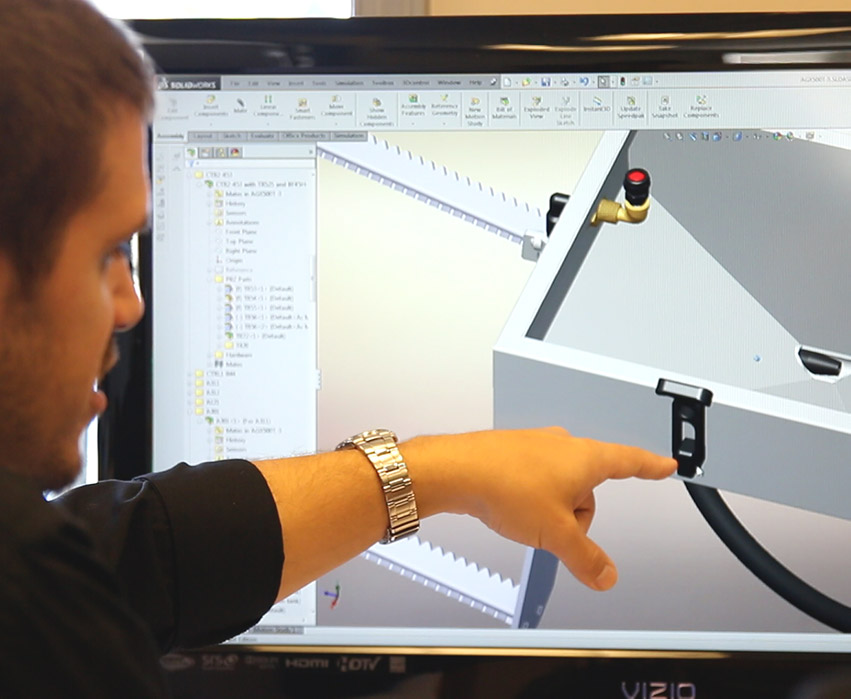

From hot and cold rolled steel to aluminum, the certified welders at PBZ can work with your structural and design requirements.