Maintaining a comfortable working environment for all employees is an important consideration for your job shop throughout the year. A job shop can be an uncomfortably hot place. Working in one during the summer raises concerns over occupational heat exposure.

With rising temperatures outside and an increase in humidity, work conditions become even more of a challenge. It’s especially difficult for welders, who must wear heavy protective gear while working and whose equipment radiates heat.

For those reasons, it’s critical to find ways to stay cool while welding.

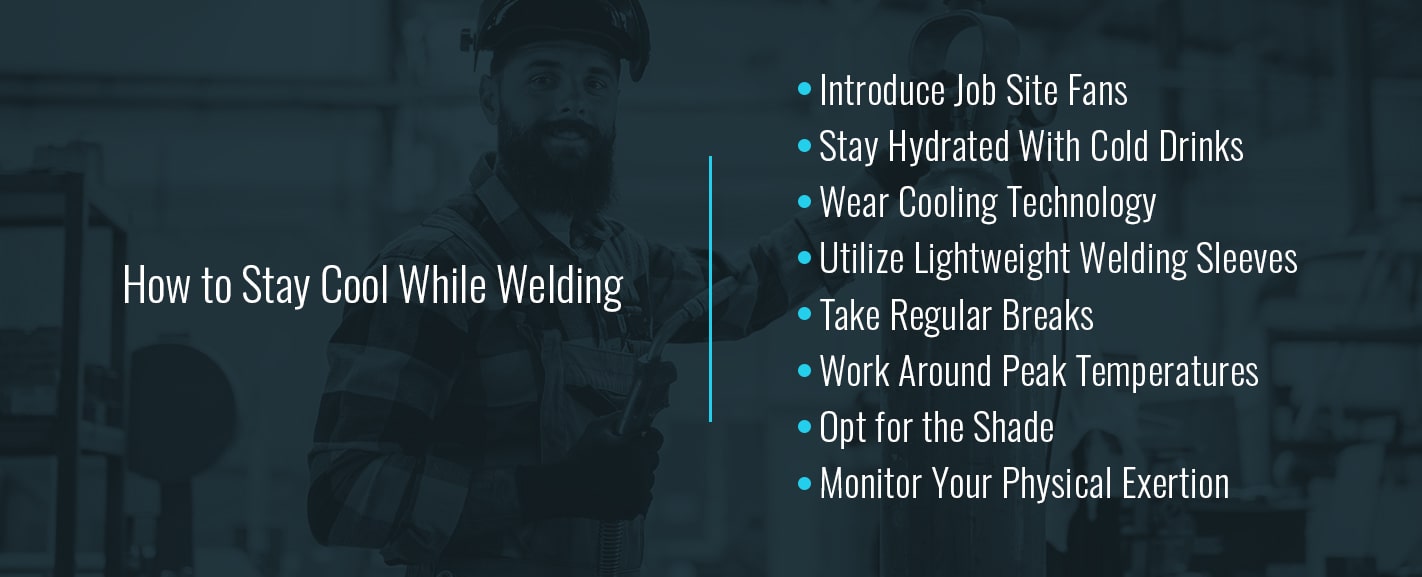

Explore the following tips for avoiding overheating while working on a welding project:

Every job shop should have a fan to promote better air circulation and keep workers feeling cool. Moving air can help reduce the risk of heat stress and support a more comfortable working environment. If your facility is large, consider choosing industrial fan options.

According to the Occupational Safety and Health Administration (OSHA), workers should drink about one cup of water every 20 minutes if they are exposed to heat while on the job.

Keeping cold drinks close by, especially those with electrolytes, is an effective way to keep welders hydrated.

Welders today have a lot of different cooling gadgets and apparel to choose from, including belts, headbands and helmets.

Most of these devices have built-in fan systems that promote airflow around the body, helping the welder avoid overheating.

Although long-sleeve shirts are preferred for protection during welding, short-sleeve shirts may be an option if a separate welding sleeve is slipped on for protection. However, never compromise personal protective gear or equipment with modifications in an attempt to stay cool.

Taking regular breaks is essential for welders working in hot environments. To prevent heat illnesses, workers should allow their bodies to cool down fully before returning to the torch.

Rest should automatically bring body temperatures down and help people feel more comfortable and relaxed. Be sure to step away for at least 10 minutes every two hours or so.

If possible, schedule welding jobs during the morning hours and any grinding for the afternoon hours. For any job shop task, heat-relief cooling towels may provide some comfort.

By avoiding peak temperatures, you can boost productivity and lower job stress. Welders can stay cooler and perform their job functions better if they can avoid working during the hottest time of the day.

For job shops with outdoor workstations, be sure to move to shaded areas if possible. Spaces with direct sunlight tend to be a few degrees hotter than shady areas.

Welders should take every measure they can to reduce heat around them and create more suitable working conditions, including dodging the sun.

Another tip for staying cool while welding is to closely monitor your physical exertion. By taking small measures to reduce their energy expenditure, workers can keep their body temperatures slightly lower.

Choosing lightweight tools is a great example of a small change that could help you exert yourself a little less and, therefore, stay cooler.

PBZ takes extra precautions to make sure our employees are not at risk for heat stress and heat-related illness. PBZ opens all its doors and supplies job site fans, and individual fans at workstations, on at-risk days to prevent heat stress. A well-stocked cooler of Gatorade is provided to the staff, and they are reminded to stay hydrated.

OSHA takes heat-related illnesses seriously. They can be prevented inside your job shop with some forethought. OSHA asserts that both workers and employers must recognize heat-related hazards and when to take emergency action.

The American Foundry Society (AFS) Safety and Health Committee recommends that you:

At PBZ Manufacturing, we aim to provide southeastern Pennsylvania with custom manufactured solutions that cut down on time and costs. We’re your one-stop shop for your metal fabrication and welding needs.

With more than 50 years of industry experience, PBZ understands how to support your business with our state-of-the-art technology and facilities. Our highly trained team of professionals can help you every step of the way.

Are you interested in learning more? Contact PBZ Manufacturing with your questions, or request a quote today!