What Is Steel Fabrication?

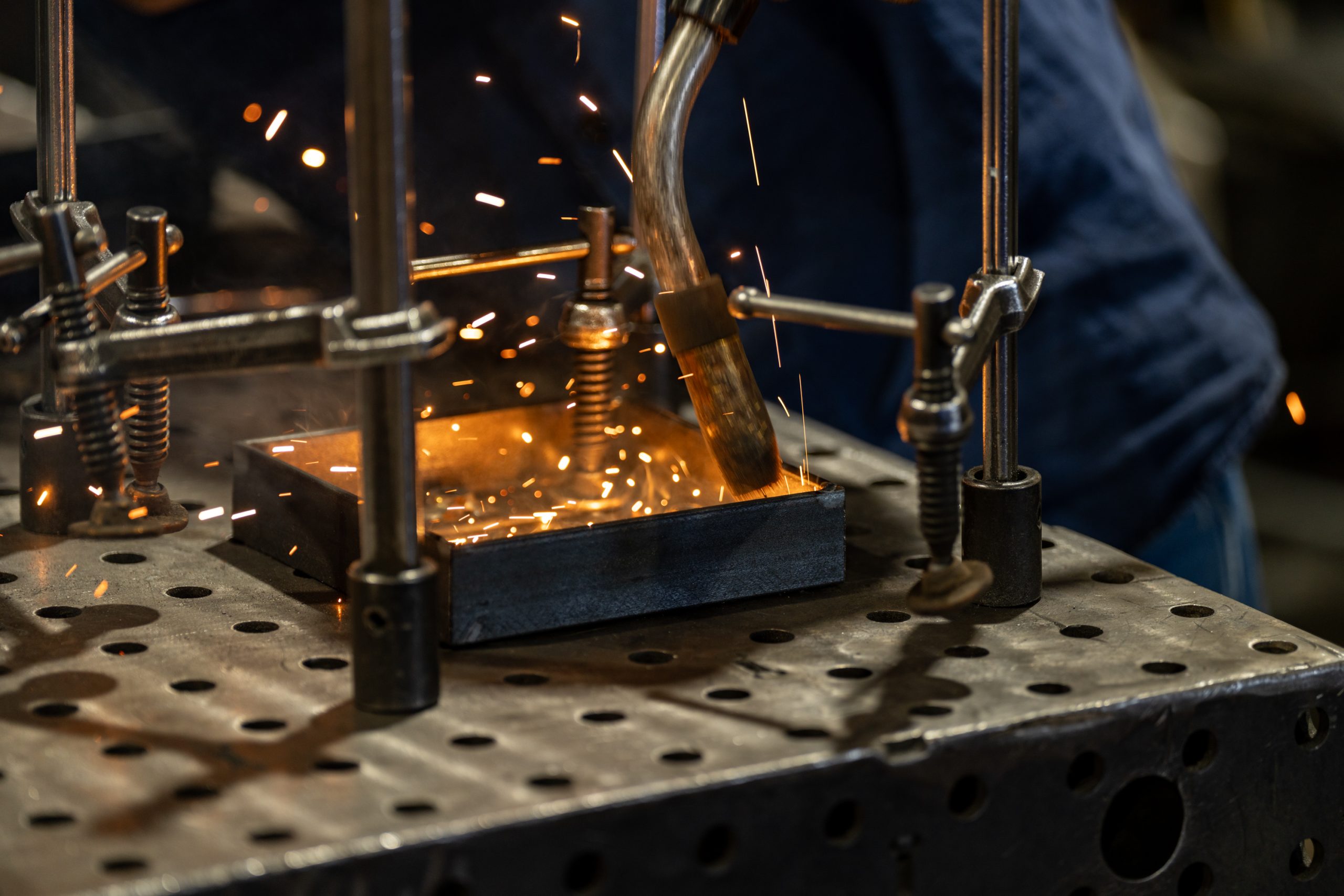

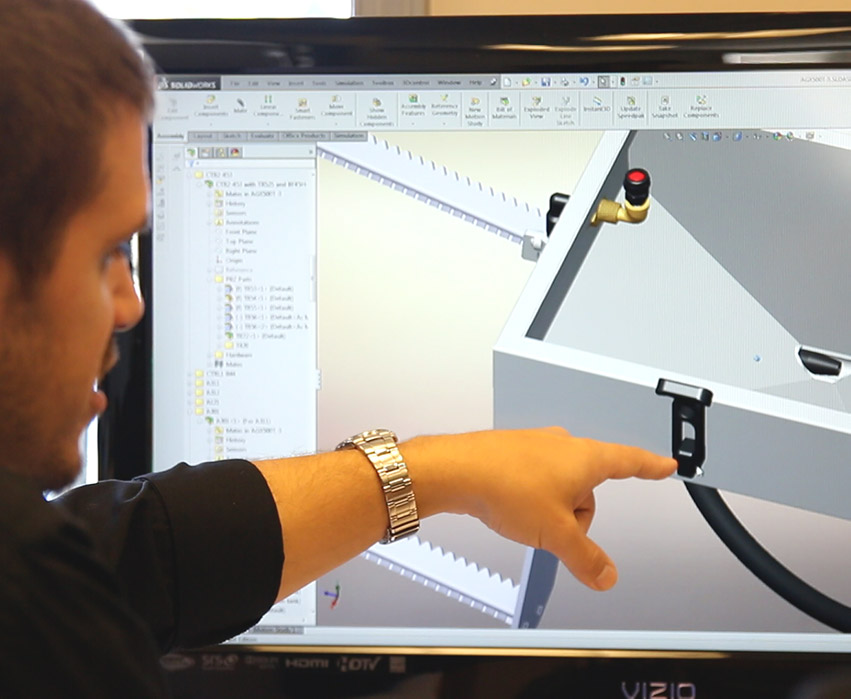

Steel fabrication is the process of developing steel parts through metal manufacturing processes, such as bending, cutting and fusing. Final steps like finishing and heat treatment help give the metal its characteristic properties and appearance.

There are numerous benefits of using steel for fabrication. Steel is durable, structurally sound, cost-effective, easy to work with, recyclable and reusable. Numerous applications rely on fabricated steel, such as:

- Mining: The mining industry uses fabricated steel and other metals for various equipment, including belt drives, mine cars and machinery. Miners need durable equipment that operates safely and efficiently under demanding conditions, making accurate fabrication a must.

- Energy: Steel fabrication is often used for energy applications like oil and gas platforms, pipelines and wind turbines.

- Transportation: Ships, trains, railways and anchor chains rely on metal fabrication services to create functional transportation products.

- Construction: Components like screws, nuts, bolts, wires and springs require high accuracy to fit correctly, making metal fabrication essential in the construction industry. Steel fabrication also helps create hand tools and hardware.