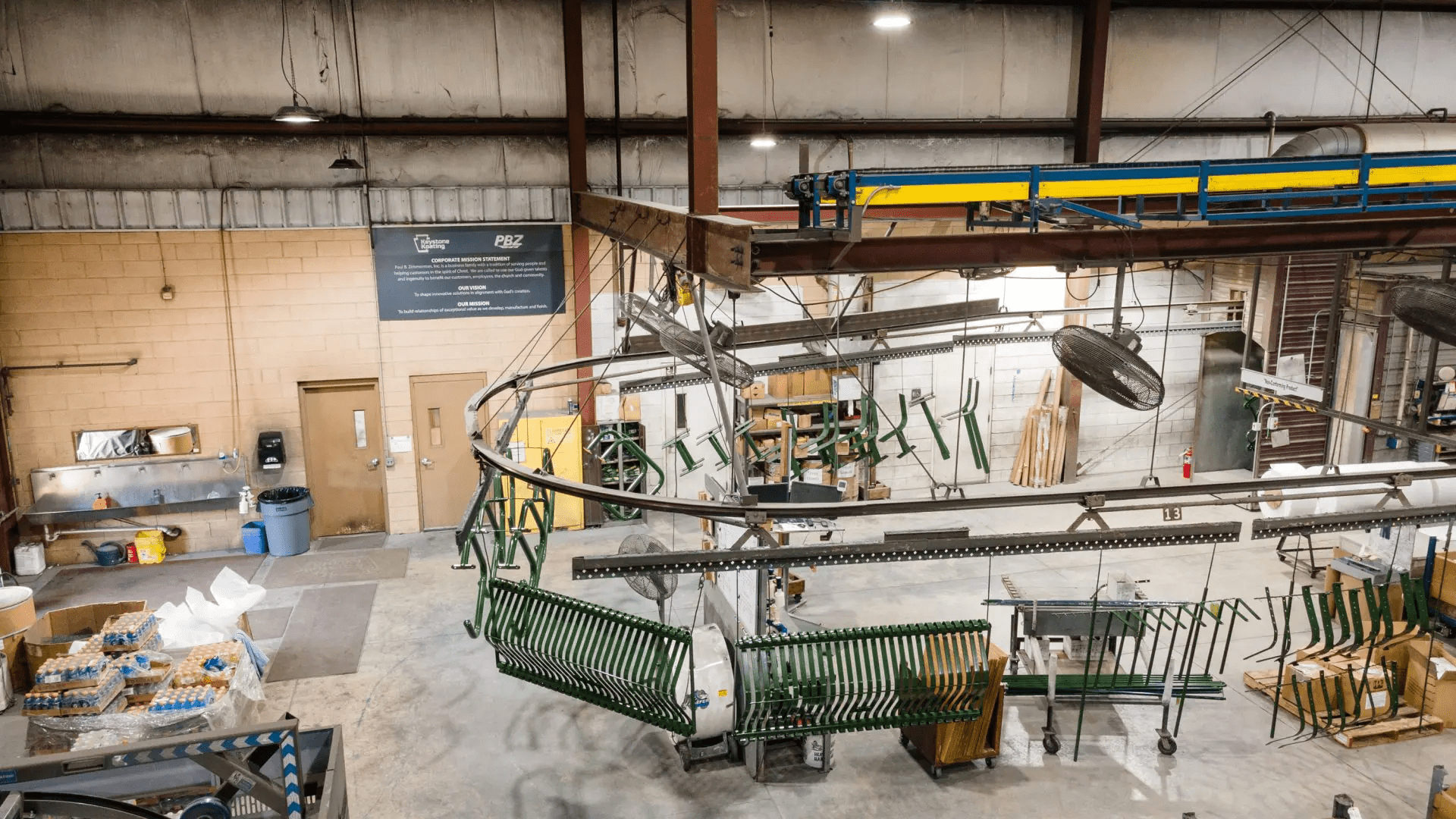

Electrocoating (e-coating) is a significant and worthwhile investment, so you need a partner that will get the job done right. That’s where PBZ can help. We’re a full-service metal manufacturer providing end-to-end services. PBZ has been a family-owned business for more than seven decades, and we have an extensive network of connections in the Lancaster community. We’ll partner with you to find a third-party e-coating company that can meet and exceed your expectations.

E-coating is a water-based finishing process requiring immersion of the workpiece. This organic method of applying paint uses an electrical current to attract the paint product to the surface of an electrically conductive part. It’s especially useful for corrosion protection and yields cost-effectiveness for high-demand production.

E-coating can boost the durability and visual appeal of your components. Partner with PBZ to find the perfect contract manufacturer to bring your vision to life with e-coating.

There are several types of e-coating paints you should examine to find the perfect fit for your project. For instance, cathodic paint has high corrosion resistance. It gains this unique quality by grounding the parts and applying a positive charge to paint particles.

At the same time, a rectifier supplies high DC voltage to anodes attached to the inside of tank walls. The electric charge shoots the particles to the part surface and drags the water out from between the part and the paint. This step causes the paint to adhere to the workpiece.

Anodic paint uses the rectifier to reverse the charge, as the cathode now sits along the tank wall and draws the paint to the positively charged area. This paint is a less-expensive alternative to the cathodic method, although it’s also less corrosion resistant.

PBZ consultants can advise you on selecting the perfect solution to balance your budget and corrosion resistance needs.

The e-coating process is time-consuming and complex, with a single color change taking six to eight hours. A pump or electricity failure could cause the entire batch of paint to fail. That’s why you need a dependable partner with backup generators and experience delivering results. PBZ has been operating in Lancaster for over 70 years, so we’ve built up a network of reliable contract manufacturers to provide your e-coating services.

Our team of supply chain and logistics specialists will guide you in planning your e-coating schedule, budget and timeline. We’ll also walk you through scoping out the big picture to determine if there’s anything else you need to complete your overall project from beginning to end.

In addition to third-party e-coating services, PBZ offers every service you might need to deliver your product to consumers. Our assembly team can help you construct the products after they undergo e-coat treatment from our partner. We can also provide shipping services from the loading dock here at PBZ to your organization, or we can even arrange to have the product shipped directly to the consumer.

Whatever manufacturing services you need, we’re a convenient single-source solution.