In supply chain management for the manufacturing industry, two assets are crucial to the success of the operation — time and money. Though this applies to many other industries, using your time and money wisely in manufacturing is especially important. One mistake or setback can cost a company thousands or even millions of dollars, depending on the operational scale and the error severity.

In supply chain management for the manufacturing industry, two assets are crucial to the success of the operation — time and money. Though this applies to many other industries, using your time and money wisely in manufacturing is especially important. One mistake or setback can cost a company thousands or even millions of dollars, depending on the operational scale and the error severity.

To avoid these costly or time-consuming mistakes, manufacturers need to streamline their supply chain management (SCM). SCM solutions can also help manufacturers coordinate with the engineers who design their products to streamline communication and production. One way to simplify your supply chain management for manufacturing is by hiring a contract company like PBZ to handle most, if not all, supply chain stages.

Table of Contents

Supply chain management within the manufacturing industry is characterized by its focus on cost-efficiency, precision and quality. It requires specialized strategies and systems to meet the unique challenges of the production cycle. Some of these supply chain management manufacturing challenges can include the nature of the products, technological infrastructure and production processes.

Consumers have become more demanding in terms of the features they expect from the products they purchase. Because of these increasingly specific requests and expectations, the manufacturing industry has seen a shift in the way certain products are made. One company can no longer be responsible for the entire conceptualization, engineering and manufacturing of a particular product. Instead, several stakeholders are usually involved in producing an item, no matter how small. In addition to meeting consumer expectations, the increased use of technology has also made the production process of many products more intricate.

Due to these changes, having a capable supply chain management system is especially important for manufacturers. With so many parts involved, it can be very easy to make a mistake — and one that ends up costing the company lots of time and money. An efficient SCM manufacturing solution will minimize the likelihood of mistakes, no matter how complicated it may be to create the product.

In the earliest days of manufacturing, one company may have been responsible for the concept, design and manufacturing of all their products. Due to the increased complexity of products, several companies are typically involved in producing one brand’s product or products. A report from CIMdata estimates that 40% to 70% of today’s consumer and industrial goods are made using procured-in parts and components. While this allows companies to specialize in certain tasks and products, it also increases the chances of miscommunication or other errors related to quality and manufacturing.

With more stakeholders involved in the modern production process, the engineer who designed a product must be able to include parts, components and sub-modules that other companies create. They must research these products and select the ones that will meet their specific design needs despite the fact that they are not immediately available. Parts suppliers are also held to higher standards to streamline the manufacturing process, as they must be more directly involved with the engineering and design stages of the products for which their parts will be used.

By having a reliable SCM system in place, manufacturers can enhance their communication practices and reduce the likelihood of any costly mistakes or misunderstandings.

Thanks to the onset of Industry 4.0, the manufacturing industry is increasingly relying on technology to complete the production process. More specifically, the Internet of Things (IoT) is transforming the way manufacturers organize their operations. The IoT encompasses all technology that can exchange information via wireless connectivity without any human assistance or prompting. With the growth of the business world’s digital components and needs, leaders in the manufacturing supply chain sector must have a significant focus on their processes’ ability to operate on these digital networks.

In addition to the IoT, the influx of remote subcontractors and suppliers involved in the manufacturing process — which is made possible by the advancement of technology — can hinder the flow of the manufacturing process as a whole. With an estimated 80% of the world’s manufacturers being subcontractors, focusing on the supply chain’s functionality will help manufacturers avoid having a weak link in their supply chain that could set back production or negatively affect product quality.

An effective supply chain impacts various aspects of a manufacturing business, from cost control to customer satisfaction, making it a critical driver in a manufacturing company’s success. Investing in an SCM strategy to optimize operations gives manufacturers a competitive edge and adequate resources to navigate industry challenges.

An efficient manufacturing supply chain will save companies significant time for several reasons. Most notably, manufacturing SCM solutions allow facilities to increase the speed at which they produce each item they must send out. Some of the ways a supply chain can minimize the amount of downtime a manufacturer experiences include:

Thanks to their focus on efficiency and increased production, manufacturers can save large amounts of money when they follow a well-designed SCM plan. In fact, 79% of companies that have what is considered a high-performing supply chain have higher levels of revenue growth than other companies within their sectors. Similarly, only about 8% of the companies with less advanced supply chains report higher revenue growth than their industry’s average rate. Some of the costs you can cut by implementing an effective supply chain process include:

When manufacturers organize their operations and have an effective supply chain, the ultimate benefit is that it improves their ability to serve and satisfy their customers. In general, we can break down the benefits SCM has for customer service into the following categories:

Company infrastructure refers to the way a company is organized to achieve its ultimate goal. This can include the equipment and technology used, the types of staff members employed and whether or not contractors are needed.

A well-designed supply chain encourages manufacturing companies to plan out their company infrastructure in a way that benefits them most. For example, one manufacturer may find the savings in cost, time and space worth the investment in a manufacturing contractor. In contrast, others may choose to spend more money on equipment, tools and technology to give themselves more control over their distribution processes. These in-house distribution systems can be very expensive depending on the products involved, so figuring out supply chain methods first will allow manufacturers to make educated decisions regarding their infrastructure.

Manufacturers can also enjoy internal support as they expand into new markets, thanks to the necessary infrastructure for efficient distribution. An SCM strategy with sustainability initiatives also contributes to the organization’s efforts to meet environmental and social responsibility goals. This active participation will overall impact the brand’s reputation and market positioning.

Managing a supply chain efficiency demands ongoing efforts that require strategic planning, technological adoption, a commitment to continuous improvement and process optimization. To maintain efficiency, organizations can follow supply chain management manufacturing best practices:

Project managers and other company leaders are constantly trying to learn how to improve production in manufacturing. There are several ways to do this, but the simplest solution is to streamline your supply chain management. As you perfect the manufacturing process at your facility, you may realize there is some room for improvement and potentially some opportunities to reduce your costs.

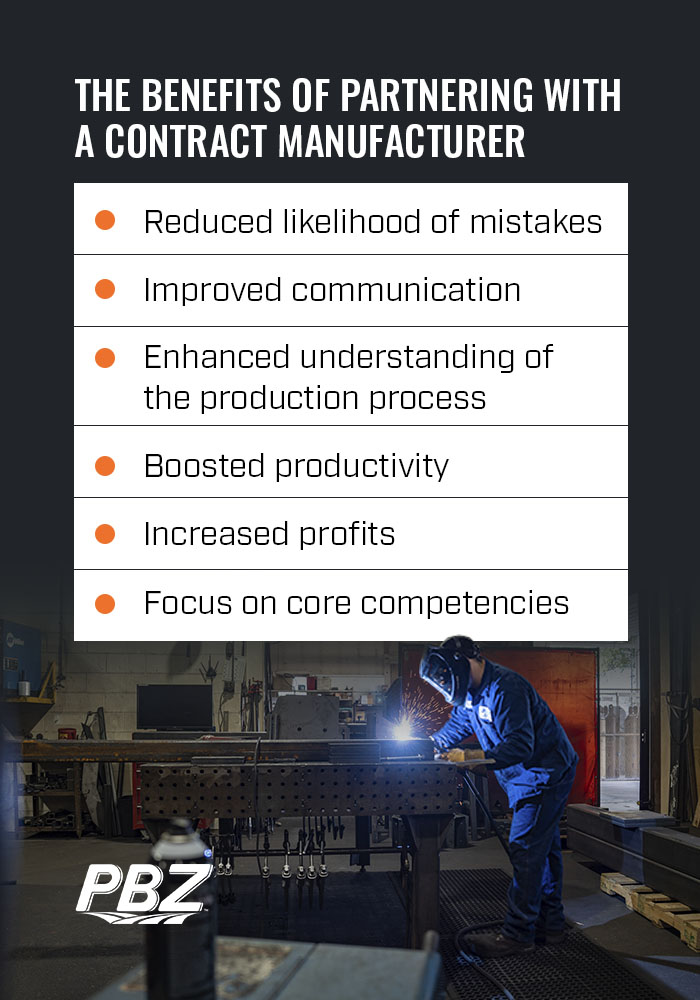

When you choose to partner with a company that specializes in contract manufacturing models, you can significantly streamline your supply chain, making it incredibly cost- and time-effective. There are a number of additional benefits to partnering with a contract manufacturer to simplify your supply chain management, including:

At PBZ Manufacturing, we understand the role of a manufacturer and the importance of having an effective supply chain management plan in place. With a focus on Resourceful Manufacturing, we make all decisions and implement process improvements based on our manufacturing supply chain process. As a full-service metal manufacturer, we can remove excess layers from your supply chain, save you money and increase your production speed. With expertise in engineering, manufacturing, finishing, assembling and shipping, we are a one-stop-shop for all your manufacturing needs.

If you’re ready to improve your manufacturing supply chain processes, contact the team at PBZ Manufacturing for more information on how we can help. We offer a ‘Rapid Reply’ option to all quotes, which means you will hear back from us within 4 business hours.

Updated March 12, 2024. Originally published October 21, 2019.